Chengdu CRP Robot Technology CO. Ltd. (hereinafter referred to as "CRP") was established in 2012, located in Longtan New Economy Function Zone, Chenghua District, Chengdu, China. It is a national high-tech enterprise focused on the research and development, production, sales and service of industrial robots and core components. It is the only industrial robot enterprise leading the preparation of five national standards in southwest China. CRP has been awarded as one of the 100 key new economy cultivation enterprises for three consecutive years, and it is also certified as National SRDI (Specialized, Refinement, Differential, and Innovation) Small Giant enterprise and Gazella Company.

01

Evaluation process support

✓ Evaluation of laser function application

✓ Arc tracking application evaluation

✓ Product pre-sale trial evaluation

✓ Order task execution evaluation

✓ Evaluation of regional major projects

02

Database support

✓ User manual, product sample book, 3D drawings

✓ Troubleshooting manual

✓ Maintenance manual

✓ Case sharing 5

✓ Online knowledge base

03

Technical support

✓Regional Supervisor - Responsible for the region

✓ Industry technical leader - responsible for the industry

✓ Delivery Manager - Scene responsible

✓ Delivery engineer - responsible for tasks

✓ Technical Engineer - responsible for the work done

04

Service personnel qualification

✓ Expert level: 3 people;

✓ Senior: 21 people;

✓ Intermediate: 32 students;

✓ Primary: Several

✓ Ability improvement: internal training, external learning, assessment and grading

CRP Milestones

2024

•Established "CRP ROBOT MALAYSIA SDN. BHD."

2023

•Robot full industrial chain coverage

•The layout of the four major overseas markets has been improvedIndustrial robots go to sea first

2022

•The first industrial robot production and research base exceeding 35,000 square meters in Southwest China was completed and put into operation.

2021

2020

•Robot machine to achieve 3000+ salesIndustrial robot integrated shipments third in China, arc welding market first

2019

•The First year of CRP Robot" The first domestic robot body marketization after the opening of the annual sales of thousands of manufacturers

2018

•The controller accounted for 50% of the domestic machine controller sales in that year; Cumulative sales of 30000 + Launched CRP industrial robot machine

2014

•Domestic industrial robot controller sales first

•Arc welding field sales accounted for 90%

2013

2012

MEDIA REPORT

CHINA ROBOT PIONEER

CRP Robot Featured in Economy Half Hour

CRP robot wins CCTV13 "News Broadcast"

CRP robot won CCTV1 "News of the World"

CRP robot wins CCTV1 "News Broadcast"

About CRP Corporate Culture

GOAL

Customer demand-oriented

TEAM

Emphasize collaboration

over division of labor

The Way Of Being A

Man And Doing Things

Low-key,truth-seeking,

tenacious

Individuals And

Organizations

Passionate,innovative

and growth

Five Systems

Supply chain system

Research and development system

Production management system

Marketing system

Service system

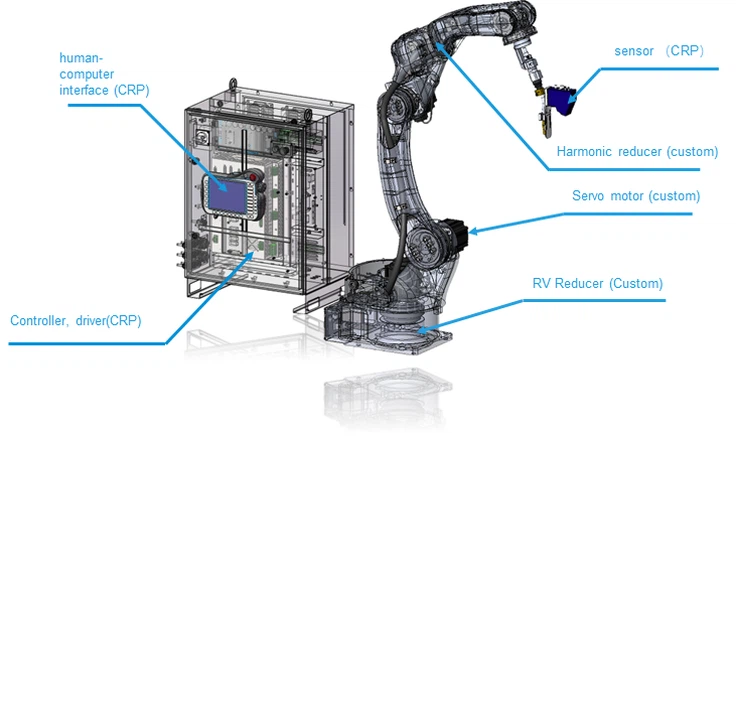

MASTER THE CORE TECHNOLOGY

Use China's best core components to build good quality robots

6

Self-developed + customized 6core component

3

A full set of electrical appliances 3 independent research and development

3

Motor, RV reducer Harmonic reducer 3 Deep customization of first-line brands

ALL-ROUND SERVICE

![]()

Value-added service

Training certification, remote consultation, upgrade services, resource replacement...

Training diversity

N ways to enable channels

Technical training, industry conferences, exhibition promotion...

Project management

60+60+ professional service staff

Digital operation and maintenance management, reduce costs and increase efficiency

Localization support

Fixed people, fixed posts, on-site support

Provide customers with on-site free technical training services

Provide specialist on-site on-site operation and maintenance services

After-sale efficiency

7*24 hours fast response service

Zero downtime spare parts service

Service globalization

6 service centers worldwide

AFTER-SALES SERVICE TIMELY, EFFICIENT, PROFESSIONAL AND SINCERE

Track after-sales results

Focus on customer satisfaction

Realize service closed-loop management

hardware maintenance

•First time to resume production

•The product can be repaired for 5 years after production is discontinued

•It can be replaced in 10 years

•Massive supply of spare parts

software maintenance

• Response within 1 day

• Level P0 BUG solution

• Response within 5 days

• Level P1 BUG solution

Demand support

• Response within 2 days

• Green channel requirements solution

• It will be completed in 1 week

• Common demand scheme

Maintenance response

• 0 days urgent delivery

Same-day dispatch

3 days

• Emergency receipt sent

STANDARD PRODUCT

DESKTOP SERIES

SMALL LOAD SERIES

MEDIUM LOAD SERIES

HEAVY LOAD SERIES

SCARA SERIES

COOPERATIVE SERIES

PRODUCT INTRODUCTION - WELDING ROBOT

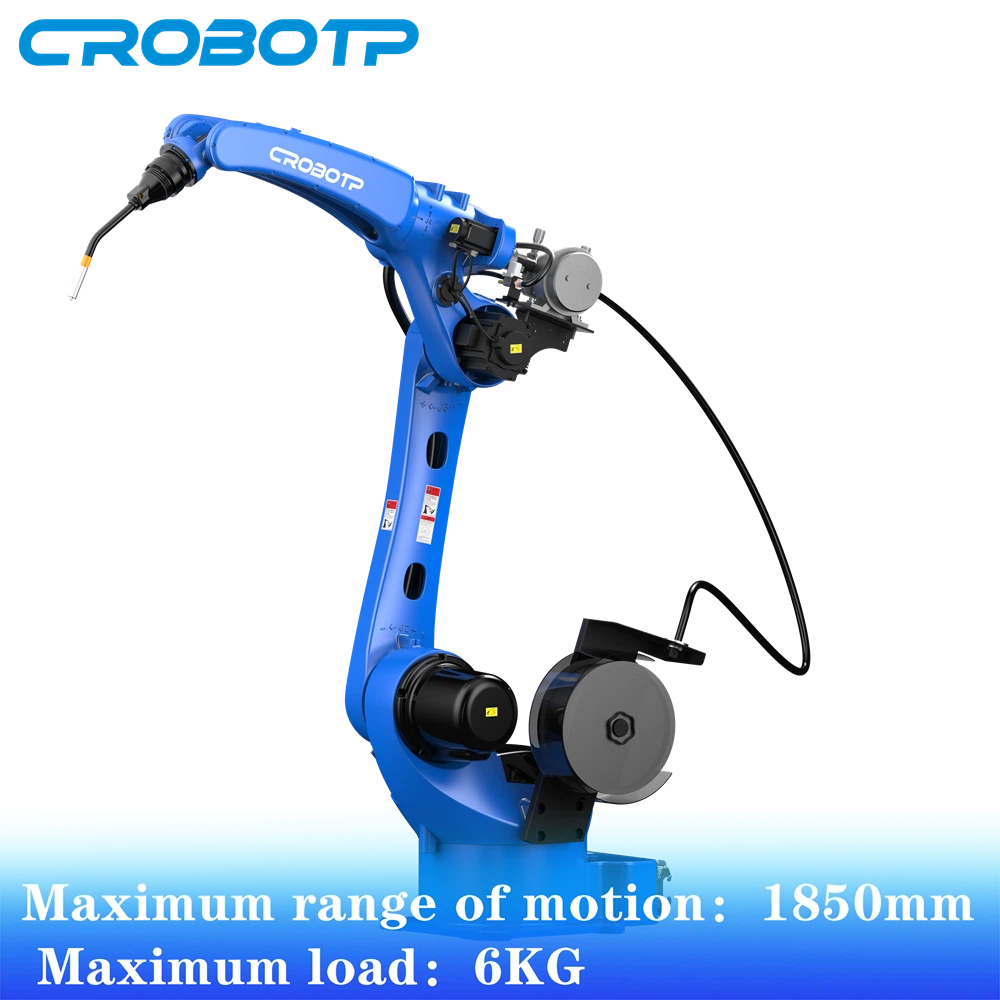

CRP-RH14-06-W

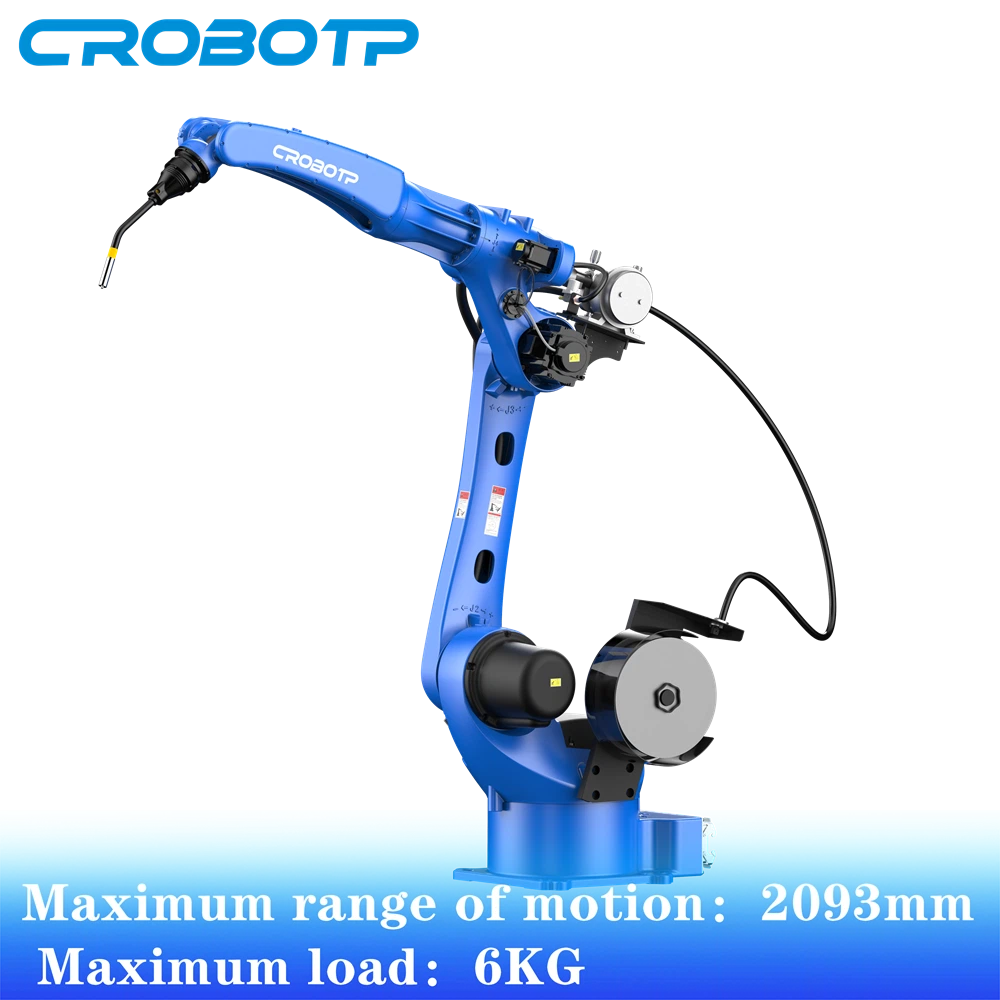

CRP-RH18-06-W

CRP-RH21-06-W

CRP-RH14-10-W

CRP-RH18-20-W

CRP-RH20-06-W

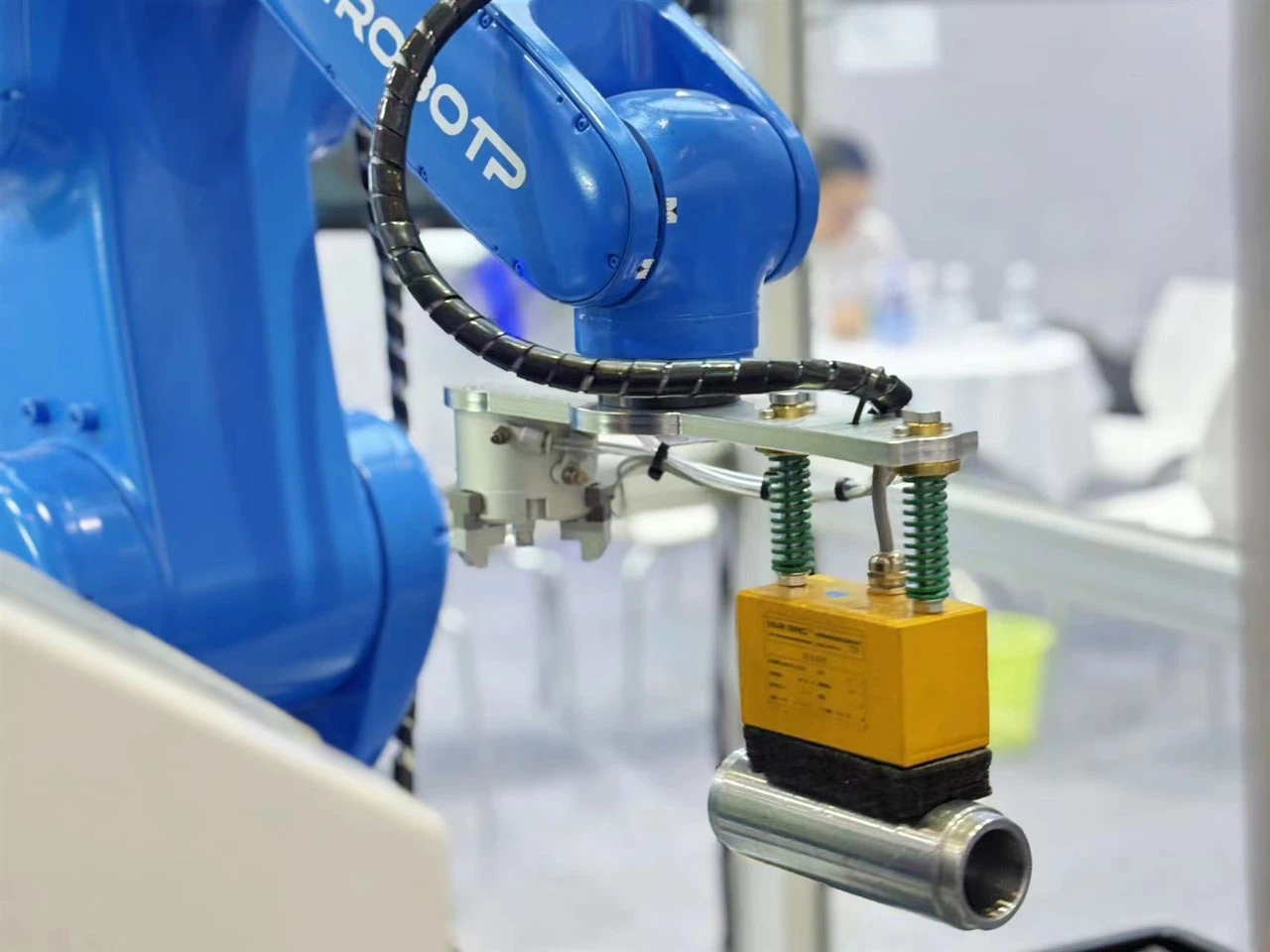

PRODUCT INTRODUCTION - INTELLIGENT WELDING SENSOR

160GB-V03

420GB-V03

Controller VLS-C03

GYXW-V2

TracerP1

TracerStudio

CAW-V2

CAW-V2

LIGHT LOAD SERIES≥1KG LOAD≤10KG

CRP-RH14-06-W

ARMSPAN:1468MM

LOAD:6KG

CRP-RA07A-08

ARMSPAN:712MM

LOAD:8KG

CRP-RA09A-07

ARMSPAN:916MM

LOAD:7KG

CRP-RH18-06-W

ARMSPAN:1850MM

LOAD:6KG

CRP-RH21-06-W

ARMSPAN:2093MM

LOAD:6KG

Small load series>10KG LOAD<50KG

CRP-RA18-30

ARMSPAN:1835.6MM

LOAD:30KG

CRP-RA15-12

ARMSPAN:1510MM

LOAD:12KG

CRP-RA18-25

ARMSPAN:1835.6MM

LOAD:25KG

CRP-RA20-12

ARMSPAN:2015MM

LOAD:12KG

CRP-RA21-10

ARMSPAN:2118MM

LOAD:10KG

Small load series>10KG LOAD<50KG

CRP-RP18-25

ARMSPAN:1530MM

LOAD:15KG

CRP-RA09-12

ARMSPAN:918MM

LOAD:12KG

CRP-RH14-10

ARMSPAN:1454MM

LOAD:10KG

CRP-RH18-20

ARMSPAN:1730MM

LOAD:20KG

CRP-RP15-15

ARMSPAN:1530MM

LOAD:15KG

MEDIUM LOAD SERIES≥50KG LOAD<130KG

CRP-RA27-80

ARMSPAN:2680MM

LOAD:80KG

CRP-RA22-80

ARMSPAN:2200MM

LOAD:80KG

CRP-RA27-50

ARMSPAN:2680MM

LOAD:50KG

CRP-RA21-50

ARMSPAN:2130MM

LOAD:50KG

CRP-RH35-100

ARMSPAN:3503MM

LOAD:100KG

HEAVY LOAD SERIES ≥130KG LOAD≤300KG

CRP-RH26-165

ARMSPAN:2606MM

LOAD:165KG

CRP-RH26-185

ARMSPAN:2606MM

LOAD:185KG

CRP-RH26-210

ARMSPAN:2606MM

LOAD:210KG

CRP-RH32-130

ARMSPAN:3255MM

LOAD:130KG

CRP-RP24-130

ARMSPAN:2485MM

LOAD:130KG

SCARA SERIES

COOPERATIVE SERIES

6 SERIES OF 50+ SELF-DEVELOPED PRODUCTS COVER 90% OF INDUSTRIAL ROBOT APPLICATION SCENARIOS

General welding industry advantage application technology: sheet welding workstation configuration

major dispositions

|

major dispositions |

selective assembly |

|

Robot body |

Gun cleaner |

|

Welding source |

Welding room |

|

control cabinet |

positioner |

sheet welding workstation configuration

functional characteristics

|

Body parameter |

||||

|

model |

RH14-10 |

RH18-20 |

RH20-10 |

|

|

End load |

10KG |

20KG |

10KG |

|

|

ARM SPAN |

1440 |

1720 |

1920 |

|

|

repeated positioning accuracy |

±0.08mm |

|||

|

Maximum Angle of each axis |

Maximum joint velocity |

|||

|

J1 |

Formal/upside down167°~-167°, (wall) hanging30°~-30° |

J1 |

169°/S |

|

|

J2 |

0°~175° |

J2 |

169°/S |

|

|

J3 |

-80°~150° |

J3 |

169°/S |

|

|

J4 |

-190~190° |

J4 |

280°/S |

|

|

J5 |

-105°~130° |

J5 |

240° |

|

|

J6 |

-210°~210° |

J6 |

520° |

|

|

Allowable moment |

J4 |

10N.m |

48N.m |

24N.m |

|

J5 |

10N.m |

48N.m |

24N.m |

|

|

J6 |

3N.m |

28N.m |

14N.m |

|

|

Allowable moment of inertia |

J4 |

0.25kg.m² |

1.8kg.m² |

1.4kg.m² |

|

J5 |

0.25kg.m² |

1.8kg.m² |

1.4kg.m² |

|

|

J6 |

0.05kg.m² |

0.8kg.m² |

0.5kg.m² |

|

|

Body weight |

170KG |

285KG |

288KG |

|

|

way to install |

Formal/upside down/wall mounted |

|||

|

IP level |

Body IP54 wrist IP67 |

|||

The design is highly compact, and can be flexibly installed on the ground or inverted.

Large working space, fast running speed, high repetition accuracy, suitable for welding, spraying, loading and unloading, handling, sorting, assembly and other applications, wide range of application.

Configure an emergency stop board independent of the control system and use a safety relay circuit to provide dual-circuit emergency stop to ensure emergency stop reliability.

. The body cable is special cable for Gaosoft robot.

Built-in three-phase transformer, 380V and 200V isolation, more stable power supply. Built-in three-phase filter to effectively improve EMC and EMI performance.

The body provides double air pipes to meet the requirements of welding and handling.

The inner diameter of the shaft hole is 46mm, which can meet the installation requirements of water cooling gun and bellows gun.

Built-in high flexibility welding cable.

G4 control cabinet parameters

|

Teaching box |

8 inch TFT-LCD, keyboard + touch screen, mode selection switch, safety switch, emergency stop button, line length 6 meters |

|

User storage |

200m |

|

Number of control axes |

6+2 axes (standard configuration 6 axes, external axes need to be selected) |

|

connector |

Digital I/O interface,22 input /22 output, COM expansion |

|

4-channel 0-10V analog output, 12-bit precision, COM extensible |

|

|

Dual encoder signal interface (for position tracking)/Ethernet |

|

|

mode of operation |

Dual USB interface, teaching, reproduction, remote |

|

motor function |

Point to point, line, arc |

|

instruction system |

Movement, logic, craft, arithmetic |

|

coordinated system |

Joint coordinates, cartesian coordinates, user coordinates, tool coordinates, base coordinates |

|

Exception detection function |

Scram exception, servo exception, user coordinate exception, tool coordinate exception, safety maintenance, arcing exception, etc |

|

Robot safety |

External emergency stop, anti-collision, safety latch and other interfaces; MC safety loop, servo softening, etc |

|

Reserved special interface |

Arc welding interface, station interface, Remote upper interface |

|

software package |

Welding/handling/palletizing/spraying is optional |

|

Other |

Power off regeneration, laser tracer, arc tracking |

|

Power supply and body interconnection cable |

5m |

|

power supply |

3-phase 380VAC 50-60HZ |

|

size |

550X785X410mm |

|

weight |

65KG |

General welding industry advantage application technology: sheet welding function

In the thin plate welding scene, the user requires high efficiency, fast programming, small splash and low welding alarm rate.

Flight arcing

Lap starting

Multiple arcing

Draw the wire after welding

Thread removal function

Fish scale welding function

Trial welding

General welding industry advantage application technology: sheet welding workstation configuration

Features of workstation configuration

01

● High beat

① The robot moves fast

② Blank line smoothing control:

Reduce long distance spacetime

③ Small line acceleration control:

High acceleration and deceleration reduces the running time at small distances

④ Flight arcing control:

When the point is not reached, the arc starts in advance to shorten the arc time;

02

● high finished product rate

① Robots and welders communicate through full digital:

Fast and stable

② Low heat control sheet process:

Very low voltage still arc stability, reduce welding heat

③ High tolerance of deviation and gap:

Smooth short-circuit transition improves the tolerance of arc pairs for error and gap

④ After welding wire pulling function:

It can effectively improve the success rate of arcing

03

● Good programming operation

① Friendly interface, easy to use

② Specially developed software version to improve programming efficiency

③ Vertical teaching devices for faster programming will be introduced

04

● Good molding effect

① Sheet, ultra-low splash:

CO2 and gas mixture can be ultra-low splash welding

② Smooth short circuit transition:

The arc is softer, has tension, and forms beautifully

③ Feed machine encoder feedback control:

When the arc fluctuates in the oil and water, it can be adjusted quickly

④ Fish scale welding function:

Can weld beautiful fish scale bead, optional

I. Robot comes with fish scale welding

II, welding machine comes with fish scale welding (optional)

05

● high security

① Unique servo softening function, J4/5/6 servo softening after the welding gun is hit, prevent damage to the body and can easily pull the robot out of the impact zone

② The safety hardware unit independent of the system can ensure the stable and rapid emergency stop of the robot when it stops unexpectedly

06

● High quality free service

① According to customer needs, free design scheme and tooling

② Headquarters professional welding process engineers can be free service

③ If you need positive and negative flip welding, you can provide free economic flip mechanism drawings

General welding industry: CRP new generation of integrated, high-performance welding robot

high speed movement

Rapid programming

Integrated design

Ultralow splash

20% Robot motion performance

30%Programming efficiency

100KHz Welding power frequency

200A Welding condition

Ultralow splash

High-performance all-digital processor to achieve three-level soft switching technology, frequency up to 100KHz welding power supply, MAG/CO2 can achieve ultra-low splash welding, and the current range is wide, 200A welding conditions still get excellent control effect.

01

Constant depth function

Suitable for uneven welds.

02

Recoil type arcing

The success rate of arcing is improved.

03

Fish scale welding (standard)

Welding thinner plates and exterior parts.

04

Features in the welding process of medium and thick plate:The thickness of the plate forming precision is low, the welding time is long, resulting in large thermal deformation, and the weld is long and thick;In order to better realize the welding stability of medium and thick plate, the following four functions are developed:

Swing arc welding

Arc tracking

Position finding and correction

Multilayer multichannel

Medium and thick plate welding function

Pendulum arc welding form

Z-shaped swing is suitable for flat welds and fillet welds

Circular arc swing is suitable for flat welds, fillet welds and filled welds (the robot's motion trajectory is shaped like spiral arc alternations)

The new orthotriangle swing is suitable for vertical welding seams to solve the defects of vertical welding root melting depth

The new positive crescent swing is suitable for bottom welding to solve the bottom welding of large gap workpieces

The new inverse crescent swing is suitable for multi-layer and multi-channel filling and cover welding.

Medium and thick plate welding function

Locating function

Locating function

The position finding function is a function that automatically corrects the path of the robot when the trajectory changes due to the movement of the workpiece position.

Classification of locating methods:

Medium and thick plate welding function

Search function calculation mode

Translational calculation

In each direction, the point difference before and after the shift is calculated.

Represents search mode: 1D,2D,3D, point.

Coordinate system calculation

The space coordinate system is established by the point position obtained from the search.

Calculate the deviation of the front and rear coordinate systems.

Represents search mode: 2D+, 3D+, face.

Center calculation

The three points on the arc are obtained by finding the position, and then the center of the circle is calculated by the three points.

Calculate the deviation between the center of the front and back circles.

Indicates the locating mode: inside and outside the circle.

Medium and thick plate welding function--Arc tracking

The arc tracker will cooperate with the swing welding, and automatically correct the bias of the weld during the welding process to ensure the accurate position of the weld.

Arc tracking is achieved without complex setup.

|

Arc tracking application range |

range |

unit |

|

Welding mode |

More than 200A DC |

|

|

Swing frequency |

2~3.5 |

HZ |

|

amplitude of swing |

2~7 |

mm |

|

welding speed |

3~10 |

mm/s |

|

Team gap |

0~4 |

mm |

|

Weld Angle |

90±45 |

° |

|

leg size |

5mm or above |

mm |

|

Collaborative function |

Line/rotation |

|

Medium and thick plate welding function

Multi-layer and multi-channel functions

Show the first weld by programming (can add the location function to find the bottom weld).

The parameter presets and saves the offset values of the number of layers and the number of tracks as parameter groups.

Invoke the preset multi-layer and multi-channel parameter set to automatically generate the track and weld the actual weld.

Hot Tags: general industry, China, manufacturers, suppliers, cheap, made in China, 6 Axis Collaborative Robot, Steel Structure Welding Robot, MIG Welding Power Source For Robot, Robotic Welding Systems, Robotic Welding Applications, Heavy 2 Axis P Type Positioner